|

|

|

|

|

|

Harrick

Scientific's Plasma Cleaner models are low-cost tabletop inductively coupled

plasma devices that serve as excellent tools for surface cleaning, surface

preparation and surface modification. Plasma treatment may be applied to a

wide variety of materials, including metals, ceramics, composites, plastics,

polymers and biomaterials.

Our plasma cleaners may be employed in a

broad range of surface engineering applications, including surface cleaning,

surface sterilization, surface activation, surface energy alteration,

surface preparation for bonding and adhesion, modification of surface

chemistry, as well as the surface treatment of polymers and biomaterials

through activation, grafting and surface coating.

Our plasma cleaners are specifically

designed for laboratory, R&D and office use. They offer inexpensive, compact

functionality. Key applications areas include materials science, polymer

science, biomedical materials, sterilization of dental and medical implants

and instruments, optical cleaning and micro-fluidics.

Links to further information on plasma

surface cleaning and surface treatment with Harrick Scientific Plasma

Cleaner models are given below: |

|

General Plasma

Information

Physics of Plasma

— what plasma is, how it is generated

and sustained, and the basics of how it interacts with a material surface

Plasma Advantages

— the advantages of plasma surface

treatment for the surface itself, process flexibility and consistency,

low-cost, ease-of-use, and user and environmental safety

Plasma-Surface Interaction

— the fundamental modalities of

plasma-surface interaction: ablation, activation, crosslinking and

deposition

Plasma Process Gases

— a guide to the use of different plasma

process gases for chemical and mechanical contamination removal, oxidation,

activation, crosslinking and deposition

Plasma Cleaner

Information

Plasma Cleaner Features

— Plasma Cleaner product features, model

options, device requirements and applied power settings

Plasma Accessory Features

— product features of our PlasmaFlo gas

mixing/metering and vacuum pump accessories

Details of Operation

— basic principles of operation, details

of operational procedure and general guidance on surface cleaning and

modification

Ordering Information

— contact and ordering information for

our low-cost Plasma Cleaner models and PlasmaFlo gas mixing/metering and

vacuum pump accessories

Technical References

— a partial listing of technical

articles and patents that reference the use of our Plasma Cleaner models

Specific Plasma

Applications

Plasma Applications: Plasma Cleaning

— the advantages of plasma cleaning for

surface preparation prior to bonding and other applications; ATR

measurements demonstrating contaminant removal following plasma cleaning

Plasma Applications: Polymers

— surface cleaning and surface treatment

of polymers, surface restructuring through polymer crosslinking, chemical

surface modification through activation and grafting, and polymer surface

deposition

Plasma Applications: Biomaterials

— sterilization of medical instruments,

adhesion promotion of biomaterials, alteration of biomaterial wetting

properties, deposition of biomaterial coatings and plasma enhancement of

biocompatibility |

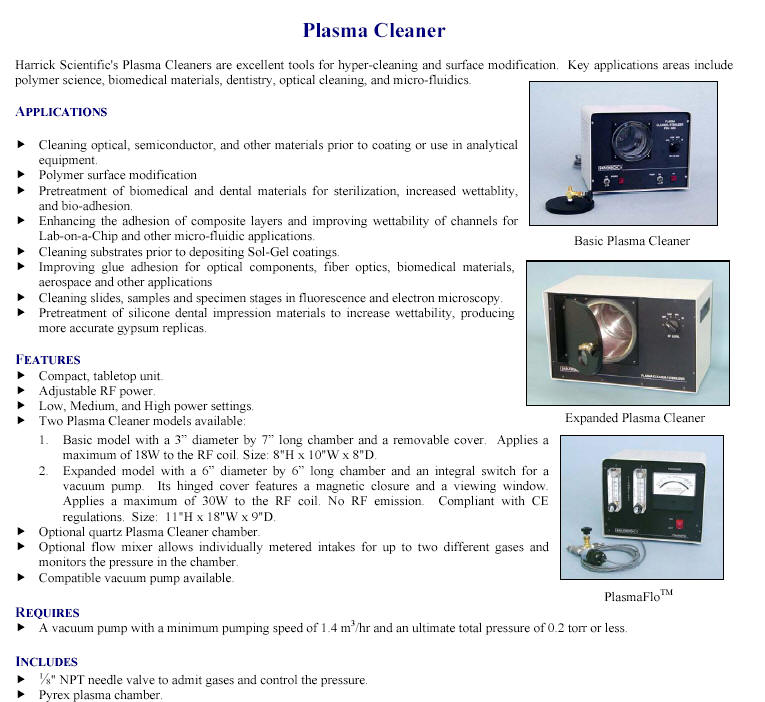

Expanded Plasma Cleaner |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nature

of Plasma |

|

|

A plasma is

a partially ionized gas consisting of electrons, ions and neutral atoms or

molecules |

|

|

The plasma

electrons are at a much higher temperatures than the neutral gas species,

typically around 104°K, although the plasma gas as a whole is at

near ambient temperature |

|

|

The plasma

electron density is typically around 1011 cm-3

|

|

|

Plasma

Formation |

|

|

An RF

oscillating electric field is generated in the gas region, either through

the use of capacitive plates or through magnetic induction |

|

|

At

sufficiently low pressures the combined effect of the electric field

acceleration of electrons and elastic scattering of the electrons with

neutral atoms or field lines leads to heating of the electrons |

|

|

When

electrons gain kinetic energy in excess of the first ionization threshold in

the neutral gas species, electron-neutral collisions lead to further

ionization, yielding additional free electrons that are heated in turn

|

|

|

Plasma-Surface Interaction |

|

|

The energy

of plasma electrons and ions is sufficient to ionize neutral atoms, break

molecules apart to form reactive radical species, generate excited states in

atoms or molecules, and locally heat the surface |

|

|

Depending on

the process gases and parameters, plasmas are capable of both mechanical

work, through the ablative effect of kinetic transfer of electrons and ions

with the surface, and chemical work, through the interaction of reactive

radical species with the surface |

|

|

In general,

plasmas can interact with and modify a surface through several mechanisms:

ablation, activation, deposition, cross-linking and grafting - see

Plasma-Surface Interaction |

|

|

|

|

|

|

|

Surface Interaction |

|

|

Plasma

treatment only affects the near surface of a material; it does not change

bulk material properties |

|

|

Plasma

cleaning leaves no organic residue, unlike many wet cleaning processes;

under proper conditions, it can achieve complete contamination removal,

resulting in an "atomically clean" surface |

|

|

Plasma has

no surface tension constraints, unlike aqueous cleaning solutions; it can

clean rough, porous or uneven surfaces |

|

|

Plasma

treatment occurs at near-ambient temperature, minimizing the risk of damage

to heat-sensitive materials |

|

|

Process Flexibility & Consistency |

|

|

Depending on

process gases and usage configuration, plasma treatment can be used for

cleaning, activation, sterilization and general alteration of surface

characteristics |

|

|

Plasma will

react with a wide variety of materials; as such, plasma can also treat

assemblies made of different materials |

|

|

Plasma

cleaning can treat odd-shaped parts with difficult surface geometries |

|

|

Plasma

treatment is highly reproducible; it is typically characterized by a greater

consistency than chemical or mechanical processes |

|

|

Low

Cost / Ease of Use |

|

|

Plasma

processing is highly efficient, with short processing times, no drying stage

and little energy consumed |

|

|

Plasma

treatment helps to avoid process yield loss due to heat or solvent damage |

|

|

Plasma

processing is easier to use and maintain than chemical or mechanical

processes; in addition, it requires no complicated chemical analysis or

maintenance |

|

|

Plasma

treatment frequently eliminates the need for solvents, along with their

ongoing purchase and disposal costs |

|

|

User &

Environmental Safety |

|

|

Plasma

treatment eliminates safety risks associated with worker exposure to

dangerous chemicals |

|

|

Plasma

processing is contained within a vacuum chamber, with little or no direct

worker exposure |

|

|

Plasma

processing operates at near-ambient temperatures with no risk of heat

exposure |

|

|

Plasma

treatment uses no harmful chlorinated fluorocarbons, solvents, or acid

cleaning chemicals |

|

|

The EPA has

classified most plasma processes as "green" environmentally friendly

processes |

|

|

|

|

|

|

|

Ablation |

|

|

Plasma

ablation involves the mechanical removal of surface contaminants by

energetic electron and ion bombardment |

|

|

Surface

contamination layers (e.g. cutting oils, skin oils, mold releases) are

typically comprised of weak C-H bonds |

|

|

Ablation

breaks down weak covalent bonds in polymeric contaminants through mechanical

bombardment |

|

|

Surface

contaminants undergo repetitive chain scission until their molecular weight

is sufficiently low for them to boil away in the vacuum |

|

|

Ablation

affects only the contaminant layers and the outermost molecular layers of

the substrate material |

|

|

Argon is

often used for ablation; high ablation efficiency, no chemical reactivity

with the surface material |

|

|

Activation |

|

|

Plasma

surface activation involves the creation of surface chemical functional

groups through the use of plasma gases - such as oxygen, hydrogen, nitrogen

and ammonia - which dissociate and react with the surface |

|

|

In the case

of polymers, surface activation involves the replacement of surface polymer

groups with chemical groups from the plasma gas |

|

|

The plasma

breaks down weak surface bonds in the polymer and replaces them with highly

reactive carbonyl, carboxyl, and hydroxyl groups |

|

|

Such

activation alters the chemical activity and characteristics of the surface,

such as wetting and adhesion, yielding greatly enhanced adhesive strength

and permanency |

|

|

Crosslinking |

|

|

Cross-linking is the setting up of chemical links between the molecular

chains of polymers |

|

|

Plasma

processing with inert gases can be used to cross-link polymers and produce a

stronger and harder substrate microsurface |

|

|

Under

certain circumstances, crosslinking through plasma treatment can also lend

additional wear or chemical resistance to a material |

|

|

Deposition |

|

|

Plasma

deposition involves the formation of a thin polymer coating at the substrate

surface through polymerization of the process gas |

|

|

The

deposited thin coatings can possess various properties or physical

characteristics, depending on the specific gas and process parameters

selected |

|

|

Such

coatings exhibit a higher degree of crosslinking and much stronger adherence

to the substrate in comparison to films derived from conventional

polymerization |

|

|

|

|

|

|

|

Gas

Sources for Plasma Surface Cleaning and Modification |

|

|

Air |

|

|

Contamination Removal (chemical) |

|

|

Oxidation

Process |

|

|

Surface

Activation |

|

O2 |

|

|

Contamination Removal (chemical) |

|

|

Oxidation

Process |

|

|

Surface

Activation (wetting & adhesion) |

|

|

Etch

(organics) |

|

|

Deposition

(glass (w/ Si))

Note: a special 'oxygen service' vacuum

pump must be used in conjunction with O2 process gas in order to avoid risk

of possible injury; inquire with Harrick Scientific for details |

|

N2 |

|

|

Surface

Activation |

|

|

Deposition

(silicon nitride (w/ Si), metal nitride (w/ M)) |

|

Ar |

|

|

Contamination Removal (ablation) |

|

|

Crosslinking |

|

H2 |

|

|

Contamination Removal (chemical) |

|

|

Surface

Modification (curing) |

|

|

Reduction

Process (metal oxide) |

|

|

Deposition

(metals (w/ M))

Note: Extreme caution must be exercised

when working with H2 process gas in order to minimize the risk of

possible injury. |

|

|

|

|

|

|

|

Features |

|

|

Compact,

tabletop unit |

|

|

Adjustable

RF power |

|

|

Low, Medium,

and High power settings |

|

|

Two Plasma

Cleaner models available: |

|

|

|

PDC-32G

(110V); PDC-32G-2 (220V) |

|

|

|

|

Basic model

with a 3" diameter by 7" long chamber and a removable cover |

|

|

|

|

Applies a

maximum of 18W to the RF coil, with no RF emission |

|

|

|

|

Size: 8"H x

10"W x 8"D |

|

|

|

PDC-001(110V); PDC-002 (220V) |

|

|

|

|

Expanded

model with a 6" diameter by 6" long chamber and an integral switch for a

vacuum pump |

|

|

|

|

Its hinged

cover features a magnetic closure and a viewing window |

|

|

|

|

Applies a

maximum of 30W to the RF coil, with no RF emission |

|

|

|

|

Size: 11"H x

18"W x 9"D |

|

|

Optional

quartz Plasma Cleaner chamber |

|

|

Optional

flow mixer allows individually metered intakes for up to two different gases

and monitors the pressure in the chamber |

|

|

Compatible

vacuum pump available |

|

|

Requires |

|

|

A vacuum

pump with a minimum pumping speed of 1.4 m3/hr and a maximum

ultimate total pressure of 200 mtorr |

|

|

Includes |

|

|

1/8" NPT

needle valve to admit gases and control the pressure |

|

|

Pyrex Plasma

Cleaner chamber |

|

|

Power

Settings |

| Description |

PDC-32G or

PDC-32G-2 |

PDC-001 or

PDC-002 |

| Input Power |

100W |

200W |

|

Applied to the RF

Coil |

| Low Setting |

680V DC |

10 mA DC |

6.8W |

716V DC |

10 mA DC |

7.16W |

| Medium Setting |

700V DC |

15 mA DC |

10.5W |

720V DC |

15 mA DC |

10.15W |

| High Setting |

720V DC |

25 mA DC |

18W |

740V DC |

40 mA DC |

29.6W |

|

|

|

|

|

|

|

| Note: A

detailed User's Manual is provided with all Harrick Scientific Plasma

Cleaner models. |

|

|

Principles of Operation |

|

|

The sample

is placed in the plasma vacuum chamber |

|

|

Process

gas(es) are admitted to the chamber at low flow rates (1-2 SCFH) using

either a needle valve or the PlasmaFlo accessory and are kept at low

pressure (~200-600 mTorr) through vacuum pumping |

|

|

The gases

are subject to induced RF magnetic and electric fields generated by a

solenoidal coil current |

|

|

Plasma is

generated through the subsequent RF/collisional heating of the electrons in

the gas |

|

|

Details of Operation |

|

|

The plasma

vacuum chamber door has an o-ring quick disconnect seal for easy access to

the chamber |

|

|

The vacuum

pump is connected to an outlet at the back of the reaction chamber |

|

|

The needle

valve can be used to break the vacuum gently, to control the pressure or to

admit a special gas for plasma processing |

|

|

The RF power

level can be adjusted by means of a three-way selector switch |

|

|

The plasma

will emit a characteristic glow, which visibly indicates the successful

generation of the plasma state |

|

|

The

temperature change of a substrate during plasma treatment is minimal |

|

|

Surface Cleaning / Modification |

|

|

The

interaction between the plasma and the surface is determined by: |

|

|

|

The nature

of the substrate and surface contaminant layers |

|

|

|

The process

gases used |

|

|

|

The pressure

and flow rate of the gases |

|

|

|

The RF power

level & length of sample exposure |

|

|

For surface

cleaning, a few seconds exposure, following pump down of the chamber and

formation of plasma, is often adequate |

|

|

Surface

cleanliness can be tested most easily by observing the wettability of the

sample: on a clean surface, water drops will not bead, but will spread out

in a uniform film |

|

|

|

|

|

|

|

Plasma

Cleaning |

|

|

Conventional

cleaning methods often fail to completely remove surface films, leaving a

thin contamination layer; additionally, solvent cleaning typically leaves a

surface residue |

|

|

Plasma

cleaner use exposes the surface to a gas plasma discharge, gently and

thoroughly scrubbing the surface |

|

|

Plasma

cleaning will remove non-visible oil films, microscopic rust or other

contaminants that typically form on surfaces as a result of handling,

exposure or previous manufacturing or cleaning processes; additionally,

plasma cleaning does not leave a surface residue |

|

|

A plasma

cleaner can treat both a wide variety of materials - including plastics,

metals and ceramics - as well as complex surface geometries |

|

|

A plasma

cleaner is most commonly used prior to adhesive bonding both to clean away

loosely held contaminant residues and to activate the surface for increased

bonding strength |

|

| Figures 1

and 2 below show the ATR spectra, respectively, of Ge and Si substrates

prior to and following surface contaminant removal via plasma cleaning. |

|

| Figure 1. ATR spectra

(qave=45°, N=20) of a Ge surface before and after plasma cleaning

with a Harrick plasma cleaner. The lower trace shows Ge coated with

a thick (about I micron) film of photoresist (AZ111). The upper

trace shows same surface after fifteen minutes of plasma cleaning

with 02, indicating Ge is restored to its original

organic free condition with the photoresist stripped off the

surface. |

|

|

|

| Figure 2. Harrick

plasma cleaner hydrocarbon removal from the surface of a silicon ATR

plate (60 reflections, q = 45°). The C-H band (bottom trace),

representing 10% absorption, is completely eliminated (top trace)

after one minute exposure to an air plasma. |

|

|

|

|

|

|

|

|

|

Surface Cleaning of Polymers |

|

|

Plasma

ablation mechanically removes contaminant layers through energetic electron

and ion bombardment of the surface - see Ablation |

|

|

Plasma

surface cleaning removes surface contaminants, unwanted surface finish from

polymers and weak boundary layers which may be present in certain processed

polymers |

|

|

Surface Restructuring of Polymers |

|

|

The breaking

of polymer surface bonds by plasma ablation using an inert gas leads to the

creation of polymeric surface free radicals |

|

|

A surface

free radical can rebond in its original polymeric structure, it can bond

with an adjoining free radical on the same polymeric chain, or it can bond

with a nearby free radical on a different polymeric chain - see

Crosslinking |

|

|

Such polymer

surface restructuring can improve surface hardness, as well as tribological

and chemical resistance |

|

|

Surface Alteration of Polymers |

|

|

The breaking

of polymer surface bonds by plasma ablation leads to the creation of

polymeric surface free radicals |

|

|

The bonding

of these surface free radicals with atoms or chemical groups from the plasma

leads to the replacement of surface polymer functional groups with new

functional groups, based upon the chemistry of the plasma process gas - see

Activation |

|

|

Typical

polymer functional groups formed through plasma surface activation and

grafting include: amine amino-carboxyl, carboxyl hydroxyl and fluorination

carbonyl |

|

|

Such polymer

surface alteration can modify the chemical properties of the surface while

leaving the bulk properties unchanged |

|

|

Surface Deposition of Polymers |

|

|

Plasma

deposition involves the formation of a thin polymer coating on the substrate

surface through polymerization of the process gas |

|

|

If a process

gas comprised of more complex molecules, such as methane or carbon

tetrafluoride, is employed, these may undergo fragmentation in the plasma,

forming free radical monomers; these in turn bind to the surface and

recombine into deposited polymeric layers |

|

|

These

polymer thin-film coatings can dramatically alter the permeation and

tribological properties of the surface - see Deposition |

|

|

|

|

|

|

|

Sterilization |

|

|

Plasma

sterilization treatment is gaining growing acceptance for disinfecting and

sterilizing medical devices |

|

|

Plasma

treatment offers the potential for simultaneous cleaning and sterilization

of medical instruments |

|

|

Plasma

sterilization is particularly appropriate for medical or dental implants and

devices that are sensitive to the high temperature, chemical or irradiative

environments associated with autoclaving, EtO or gamma sterilization,

respectively |

|

|

Adhesion Promotion |

|

|

Many

biomaterials have a low to medium surface energy, making it difficult to

effectively apply adhesives or coatings |

|

|

Plasma

surface activation leads to the formation of surface functional groups that

increase surface energy and improve interfacial adhesion for biomaterial

bonding |

|

|

Wetting Properties |

|

|

Most

untreated biomaterials have poor wettability (hydrophilicity) |

|

|

Plasma

surface treatment has been used to enhance or decrease the wetting

characteristics on a wide variety of biomaterials |

|

|

Surfaces may

be rendered hydrophilic through plasma activation, and may be rendered

hydrophobic through plasma deposition of thin films |

|

|

Low-Friction & Barrier Coatings |

|

|

Some

silicones and polymers such as polyurethanes have a typically high

coefficient of friction against other surfaces |

|

|

Plasma

coating deposition of a lower coefficient of friction polymer coating yields

a more lubricious surface for biomaterials applications |

|

|

Plasma

coating deposition can also be used to form thin, dense barrier coatings

that decrease permeability to liquids or vapors for biomaterials

applications |

|

|

Biocompatibility |

|

|

Biomaterials

that come in contact with blood or protein require special surface

treatments to enhance biocompatibility |

|

|

Plasma

activation of biomaterial surfaces prepares them for cell growth or protein

bonding; additionally, biomaterial surfaces may also be modified to decrease

the bonding of proteins |

|

|

Biomaterials

with modified surfaces exhibit improved "biocompatibility", including

enhanced cell adhesion, improved cell culture surfaces, non-fouling surfaces

and promotion of selective protein adsorption |